Engineer Extraordinaire.

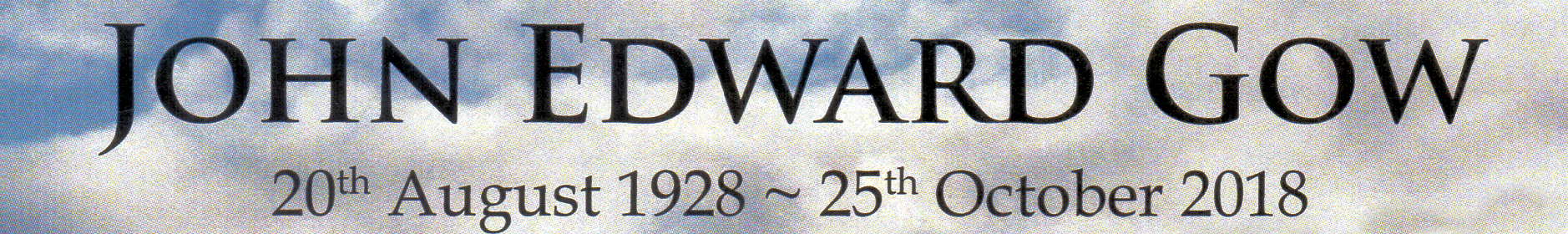

John Edward Gow, always know as Jack, was born at Caulfield on 20th August 1928 to modest parents. Educated at Caulfield State and Brighton Technical Schools (where he did Sheet and Metal Working), Jack started his working life with Victorian Producers Corp Wheat Group as a General Clerk but 12 months later, he joined Victorian Railways as a sheet metal worker and lamp maker for 4 years. During this time, he also studied drafting at RMIT.

John Edward Gow, always know as Jack, was born at Caulfield on 20th August 1928 to modest parents. Educated at Caulfield State and Brighton Technical Schools (where he did Sheet and Metal Working), Jack started his working life with Victorian Producers Corp Wheat Group as a General Clerk but 12 months later, he joined Victorian Railways as a sheet metal worker and lamp maker for 4 years. During this time, he also studied drafting at RMIT.

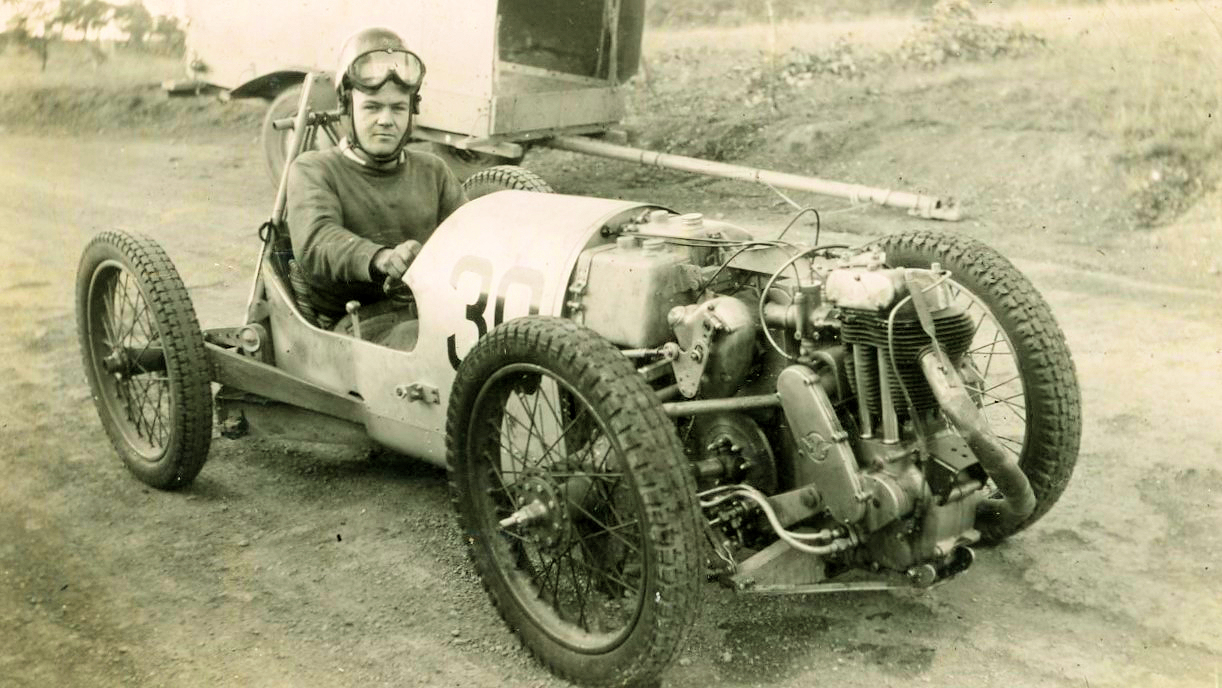

In 1949, Jack joined the Commonwealth Aircraft Corporation as a draftsman where he rose to be Group Leader – Drafting – Fuselage. Then moved to Holden, Nissan and back to Holden as a contractor. Along the way he found time to, in collaboration with a friend, design and build a most remarkable race car, the WGM Special.

Jack takes up the story:

“When I started at Commonwealth Aircraft Corporation (CAC) in January 1949, I was included with a group of  newly qualified engineers. We went straight into the Drawing Office to work on the CA22 Trainer, later known as the Winjeel. The first drawings I worked on were of the tail-plane, engine cowls, fuel tank & oil tank. After this stint in the Drawing Office I was sent down into the workshops and spent 2 weeks in each department, finishing at the flight hanger checking Mustangs for acceptance flight by the RAAF pilots.

newly qualified engineers. We went straight into the Drawing Office to work on the CA22 Trainer, later known as the Winjeel. The first drawings I worked on were of the tail-plane, engine cowls, fuel tank & oil tank. After this stint in the Drawing Office I was sent down into the workshops and spent 2 weeks in each department, finishing at the flight hanger checking Mustangs for acceptance flight by the RAAF pilots.

On return to the Drawing Office we started the redraw for the production trainer. Soon after this I went to work in the Chief Engineer Mr Tom Air's office doing various jet fighter studies using either Nene or Avon CAC built jet engines. This finalised into the locally built Sabre where the Avon replaced the General Electric engine. We also started the drafting of the twin jet fighter CA23; this was stopped in 1953.

After the Sabre went into production, we did a study for the UK Department of Defense fitting test equipment to flight test Hawker de Havilland Blue Jay air to air missiles, into two Sabre Jets. These were used to test the Blue Jay at the Woomera Proving Grounds, as the UK aircraft could not fly high enough.

In 1956 we started on the CA28 crop duster redesign of the Wirraway and then fitting a navigation aid (code name Wombat) into the Neptune long range search aircraft; we were also developing a fire extinguishing service for the engines of the Neptune. When they started to develop the Dassault Mirage fighter program, I was advised that I would be sent to France to work on drawings. That, and the fact that we never had a long out-look for work, I decided to leave in July 1959 and go to G.M.H. as a Senior Draftsman.

I started at Holdens on 22 July 1959 as Senior Layout Draftsman. This was also a culture shock as I had to learn to draw their way, no drafting machines, layouts on gridded painted metal sheets and all details full size on fibreglass or linen sheets. The FC Holden was on sale then, the FB Holden being tested and prepared for production in Jan 1960.

The drawings being completed were for the EJ to be released July 1962. The first senior job was the EK grille & later the underbody for the HD Holden. I remained on underbodies for HK & finally HQ in 1967. When this was finished in October 1968, I was transferred to the Design section as an Engineer working for Reg Hall, one of the original engineers that went to USA on the original Holden in 1945.

While in the Design section as a Project Engineer I worked on body panels on the whole, except a short time on plastic consoles. In April 1972, I went to Port Elizabeth plant in South Africa to assist in resolving start-up problems on Holden vehicles. On return I worked on Torana and studies for replacement to the HQ Holden. This resulted in selecting the Opel Commodore to be modified by Holden to take Holden & South African Powertrains and durability requirements. In October 1974, I was promoted to Body Engineer and later in Aug 1975, went to Germany with Hugh Videion, two draftsman, a styling representative and a Toolroom representative to start the development work.

In 1979 I was the Engineering representative included in a Toolroom modernisation trip. This included Germany, America & Japan. At this time Opel was starting the J Car world car program. This was the start of the Camira program in Australia. Later, in September 1980, I was promoted to Executive Engineer Body. While in this position I looked after Camira then later, I started the VN program and stayed on this until the major design work was completed. “

One of Jack's last major works was the design and development of the VG Utility. The 'normal' design methods proved too expensive to justify the program, so Jack was set to work with John Phillips, to come up with a low cost design.

John Phillips remembers: "The styling was supervised by Mike Simcoe. The VG project was considered to be too unwieldy to include with other projects underway in Engineering so Jack and I used to daily traipse out to Millard in Heidelberg, the drafting company used for all VG production layout and detail drawings. So, the VG design and drafting originated in a converted tin shed in Heidelberg! They later moved to more civilized quarters in Croydon.

I was lucky enough then to follow the Ute through the prototype stages which included two round Australia test trips then on to production. The release took place at a farm in Tamworth. All up, it was a great program mainly because it was so self contained."

Roger Gibbs recalls: "Seeing the origin of the WGM race car name made me think when Jack handled the design of the V-car Holden Ute when we brought it back. Jack gave the program its code name: VG. I asked him about it once, the V is obvious but he said the 'G' was for 'Gow'. Good luck to him. Two vehicles named after him.”

During his time at Holden, Jack with a team used to go into the outback to test out the new prototypes. A quote from GMH's magazine ‘Commodore’ states “the prototypes were shipped about 200 kms out of Melbourne in closed transports then driven to the far side of the black stump under the cover of darkness”.

Jack finally became Manager, Current Product Engineer in Dec 1986 until he retired from Holden in Dec 1988.

Following Holden, he went to Nissan (Clayton) where he spent the next five years as Manager – Product Development & Manufacturing – Planning (No mean feat, as he held no formal qualifications). After 1995, he spent the next 5 years working as a contractor, mainly for Holden, covering amongst other things, the Vectra release in 1998.

Marrying Kath in 1956, the Gow’s had 5 children and 7 grand children and lived all their married life in the Burwood area. He even found time to design and build their first family home in Murray Drive, Burwood.

After suffering a stroke in 2003, Jack experienced a major change in lifestyle but was still a keen supporter of the Retirees Club and attended the Lunches right up until shortly before his passing. (Thanks to Julie Gow )

ooo000ooo

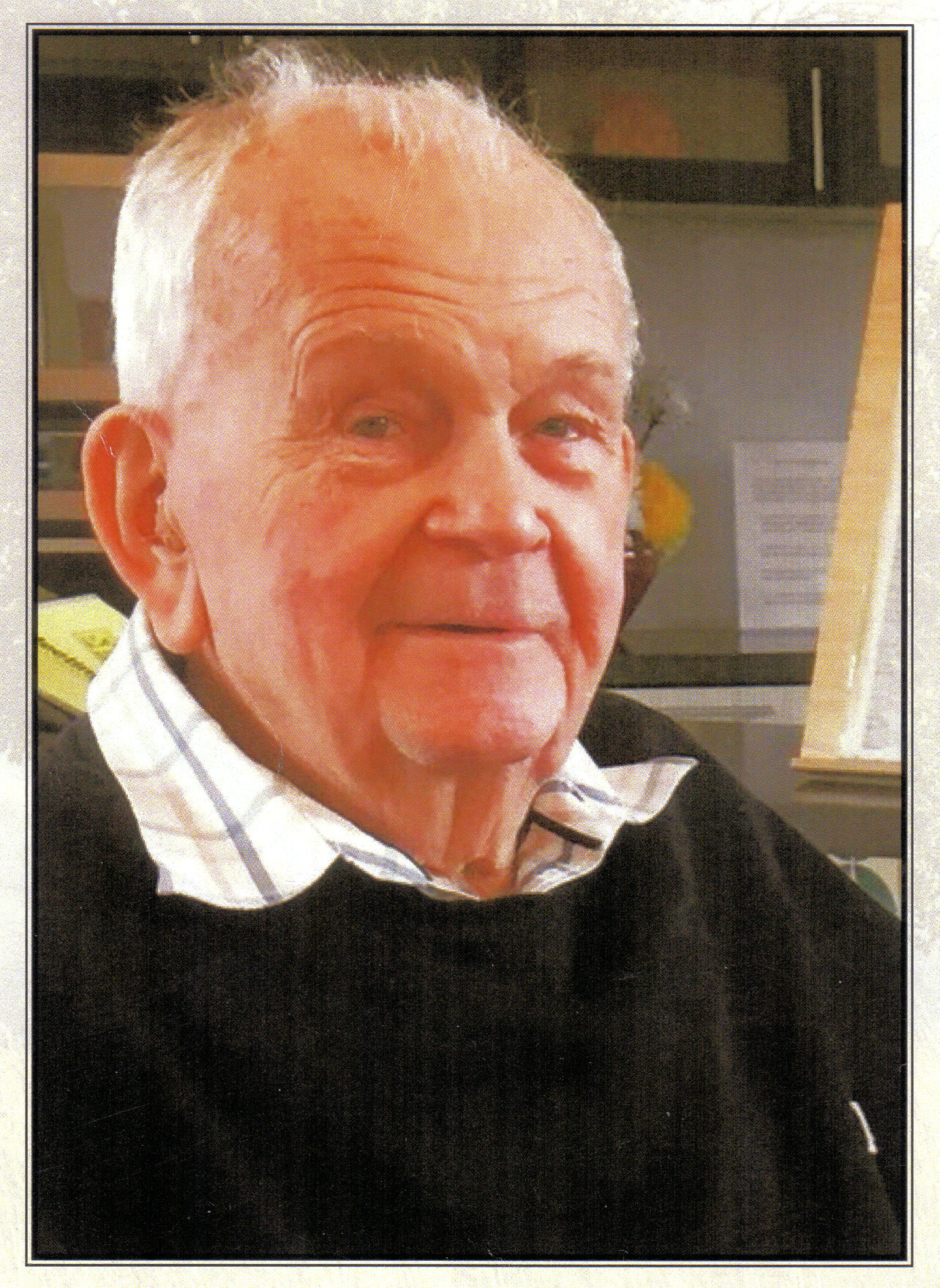

While Jack was at CAC he met A.M. 'Maurie' Wheeler, another young apprentice of similar interests, and soon became firm friends.

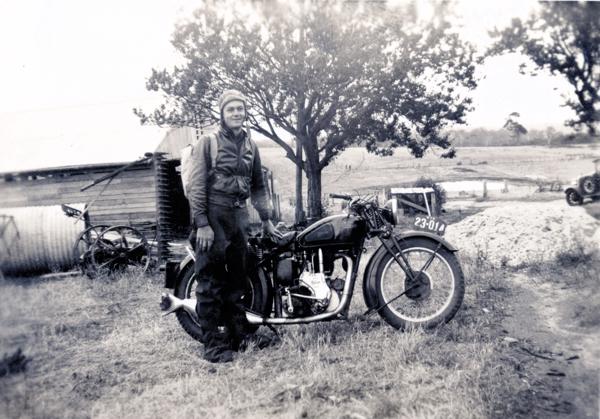

In 1950, at age 22, Jack and Maurie decided to take on the task of building a racing car to compete in the then Formula 3, 500cc class. Both being engaged in the Aircraft industry, it is no surprise that the car design was revolutionary in that it incorporated many features which owed more to Aircraft design than to the Automotives of the day. Jack did the body and chassis work, Maurie concentrated on the mechanical aspects. The car was known as the "WGM Special", and was regularly driven by Jack in Hill Climbs and races at local tracks. The 'W' in the name was for Maurie, the 'G' for Jack, and the 'M' for Motors, which Jack said was a tax dodge!

The WGM had a Y shaped boxed chassis and Matchless G80 engine mounted up front with a primary chain back to a Norton gearbox and a secondary chain driving the front wheels. Rear suspension was De-Dion with rubber bands. The forward mounted engine and fairly high centre of gravity made the handling interesting!

Significantly, this was the first car in Australia to feature disk brakes, which Maurie and Jack designed and made themselves after experience with the ‘Winjeel’ trainer aircraft.

Jack maintained his interest in the car until he married and had to turn his attention to other, more pressing things, such as bulding the first house for his new family himself. Maurie continued to race the car until it let go a crankpin during the curtail raiser to the 1956 Albert Park Grand Prix. The car was then laid up until Mauri retired in 1981 and started to restore it. He passed away in 1993 and the car was sold to the son of a friend, Chester McKaige. Chester fully restored the car and ran it in the 1996 Rob Roy Hill Climb, the same race that the car first took to the track in 1952. He even managed to get Jack back into the car to drive it!

Thanks to Chester McKaige, we are now able to bring you the story of this amazing car and its history.

{gallery}Jack Gow{/gallery}

Click here for a video of the first time the engine was started after rebuild.

The WGM racing car was built by Maurie Wheeler and Jack Gow during the period of 1950-1951, to comply with the then Formula 3, 500cc regulations.

It was originally conceived to provide something different and more interesting than the general run of rear engined ‘Cooper’ type vehicles. In the construction the sheet metal and fabrication was done by Jack and the mechanical work and machining by Maurie. Between them they put in 3-4,000 hours of work on the car as a conservative estimate.

It was raced with some success and due to its light weight was quite competitive. The first public appearance was Rob Roy during 1952 and the car appeared later at Templestowe Hillclimb, Fishermans Bend, Altona and Darley race meetings. Its last appearance being the Argus Cup, a handicap race over 16 laps for racing cars at the Albert Park circuit at the time of the 1956 Melbourne Olympic Games.

Maurie Wheeler died in 1994, but until his recent passing, Jack Gow still took a keen interest in the car.

The WGM is currently owned by Chester McKaige of Tasmania.

DESIGN FEATURES

General Layout

Front wheel drive with the engine mounted ahead of the front axle.

Wheels independently mounted at the front and a beam axle at the rear.

The chassis is a backbone box section of riveted aluminium alloy.

Bodywork of aluminium alloy except for the nose cone which is fibreglass.

Engine

A heavily developed 1948 500cc., single cylinder Matchless G80, the compression ratio raised to 12:1, a domed racing piston and an Amal racing carburettor was also fitted. Steel flywheel and a re-designed and strengthened crankpin. The drive side of the crankcase was reinforced and larger main bearings fitted along with high lift racing cams, Austenitic steel valves and chromium copper valve guides. An auxiliary gearbox was fitted to the timing side of the engine to drive a diaphragm type fuel pump and an electric tachometer generator.

Gearbox

Norton motorcycle 4-speed and clutch with the foot change lever altered to hand control on the right hand side of the cockpit.

Front Axle

The front wheels are independently mounted on transverse wishbones with their inboard ends attached to brackets on the chassis box. The outer ends of the wishbones are connected to a full length fabricated king pin member with universal swivelling ends. Suspension is by ‘bungee cord’. Rotary friction dampers are fitted to the upper inboard wishbone pivot shafts. Drive is through splined shafts and Holden universals to the front wheels.

Rear Axle

The rear axle is a beam type of high tensile steel tube with the hubs mounted on two radial ball bearings at each end. It is located on the centreline of the chassis at the rear in ‘De Dion’ fashion, with the mounting free to pivot or slide vertically. The outer ends of the axle are located by fore and aft torque members which are attached to the chassis at their front ends. Suspension is by ‘bungee cord’ and steel cable mounted on aircraft control pulleys. ‘Hartford’ type dampers are fitted on each side.

Steering

From the steering arms on the king pins, divided tie rods with swivel ends are attached to a verticlly pivoted sector shaft mounted on the chassis centreline. From the sector shaft, aircraft steel cables run back through a series of cable pulleys to a drum mounted on the lower end of the steering column with an intermediate pulley system to give a gear reduction. Prior to this system the car was fitted with a handlebar type steering.

Brakes

Disc brakes are fitted front and rear and these were designed by Maurie as a result of his experience working on the braking system of the ‘Winjeel’ trainer aircraft.

Two master cylinders are fitted (BMC), one for the front and one for the rear and are interconnected to give proportional braking.

In addition to the foot pedal, a hand lever on the left side of the cockpit allows the brakes to be applied by means of a ‘Bowden’ cable operating on both cylinders. (Note: Triple pot cylinders on front discs)

Wheels

Normal motorcycle rims spoked directly to the hubs which were also home made.

|  |  |

In 1995, Maurie Wheeler wrote his version of the history and faxed it to Chester McKaige, and it is available here.

Chester has also added some extra information:

"Maurie and Jack were apprentices at CAC and Maurie worked with my father in the drawing office. Maurie went on to design rockets at Woomera.

After retirement, Wheeler stripped the engine and replaced the crank pin and valve. He never fired it up.

He lived in Moorabbin and when he died, his son Peter sold everything, the car the last thing to be disposed of.

I got a tip off from my father who told me to go and see the car. Wheeler’s son was about to put it in a Shannon’s Auction. On impulse, I took my cheque book and ending up buying the car.

At that stage I was the Marketing Manager at Penrite Oil and my boss said go and get it now which I did, bringing it back to the factory on a truck. That was on a Monday, and it ran for the first time the following Thursday.

The car is unique. It is front wheel drive, first car fitted with disc brakes in Australia and was built from mostly aircraft parts scrounged or pinched from the scrap bin. Maurie designed the brakes on the Wingeel Trainer aircraft and copied his design on the car. It has a 500cc Matchless engine and Norton gearbox. Suspension is bungee cord. Jack did all the testing, Maurie drove it at most of the events it competed in.

When I bought it, it had last ran at Albert Park in Tourist Trophy Race in 1956, but dropped a valve. Prior to that it competed at Darly, Rob Roy hill climb, Ballarat, Templestowe and Geelong Speed Trials.

I restored it back to its former self and it featured on the poster for Geelong Speed Trials in 1997. I also ran it at Calder Park. It was built as a hill climb car. It is very narrow, so I have to engage someone to drive it, usually my brother in law.

It runs on methanol with a compression ratio of 14:1. I rebuilt the engine and that video was first time it ran again. Because it is FWD the jack is needed on one side and a set of rollers on the other.

I have made a couple of improvements like a larger fuel bowl and replaced the bungee cord, but it is basically the same as it was in 1956. Also got rid of the horrible green paint. Looks better in polished aluminium!

I visited Jack in 1998 and asked him to drive the car up Rob Roy hill, which he did. That was a “magic moment”.

The WGM stood for "Wheeler Gow Motors", as Jack said, the "Motors" was a tax dodge.

The WGM Special has featured in a number of publications including the A to Z publication of Formula Racing Cars of the world."

Chester McKaige has also kindly extended an invitation to anyone visiting Tasmania to call and view the car. However, please be sure to contact Chester at

Chester McKaige

Carrick House

6 East Street

Carrick 7291

Tasmania